The introduction of 3-D printing has proven to revolutionize the industrial world in an incredible way that no other product has in decades. It has numerous advantages, including the ability to create complex geometrics, reducing waste and the need for less or no tooling for smaller batches, etc. Even better, numerous companies offer top-of-the-line metal additive manufacturing machines designed to improve efficiencies, reduce emissions, and reduce waste.

Common Types of 3D Machine Manufacturing

There are seven categories of additive manufacturing processes which vary based on the machine technology and material used. These include:

Material Jetting

This technology stands out from the rest thanks to its ability to generate accurate parts with a fine surface finish. It involves jetting the material onto a build surface using a Drop on Demand or continuous approach. Once jetted, the material solidifies, after which the object is built layer after layer.

VAT Photopolymerization

VAT photopolymerization involves using a highly viscous photopolymer resin to construct a model. It is characterized by using UV light to cure or harden the model. The platform then moves the model down after the formation and curing of each layer.

Powder Bed Fusion

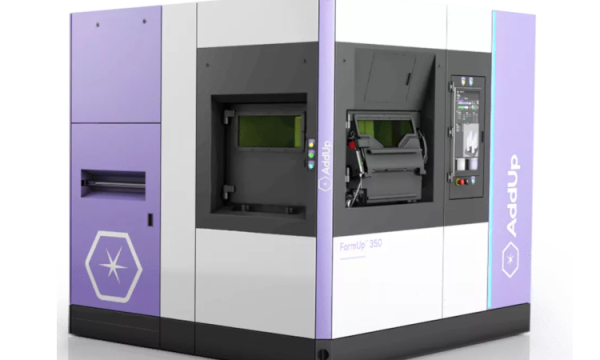

Generally, pbf additive manufacturing technology uses a heat source, usually a laser or electron beam, to sinter or fuse the powder particles. The process is one layer after another until the model is fully formed.

Material Extrusion

This additive manufacturing technology is where a continuous filament of thermostatic or composite material is selectively dispensed through an orifice or nozzle to construct a 3-D part.

Sheet Lamination

Sheet lamination is an additive manufacturing technology that involves staking thin sheets of material, mostly paper, metal or plastic foil. The materials are then bounded together layer after another using welding, heat, adhesive or pressure to form a 3-D object.

Direct Energy Deposition

Direct Energy Deposition is a 3-D printing technique that uses a laser, plasma arc or electron beam to melt a material as it is being deposited. Additional material is added in layers; after which it solidifies to build or repair new features on a substrate.

Binder Jetting Process

Binder jetting involves the selective dispensation of the binding agent, usually a binding liquid, into a thin layer of powder particles, usually ceramics, foundry sand, composites or metal, to construct high-value 3-D parts. The process is done one layer after another until the object is fully formed.